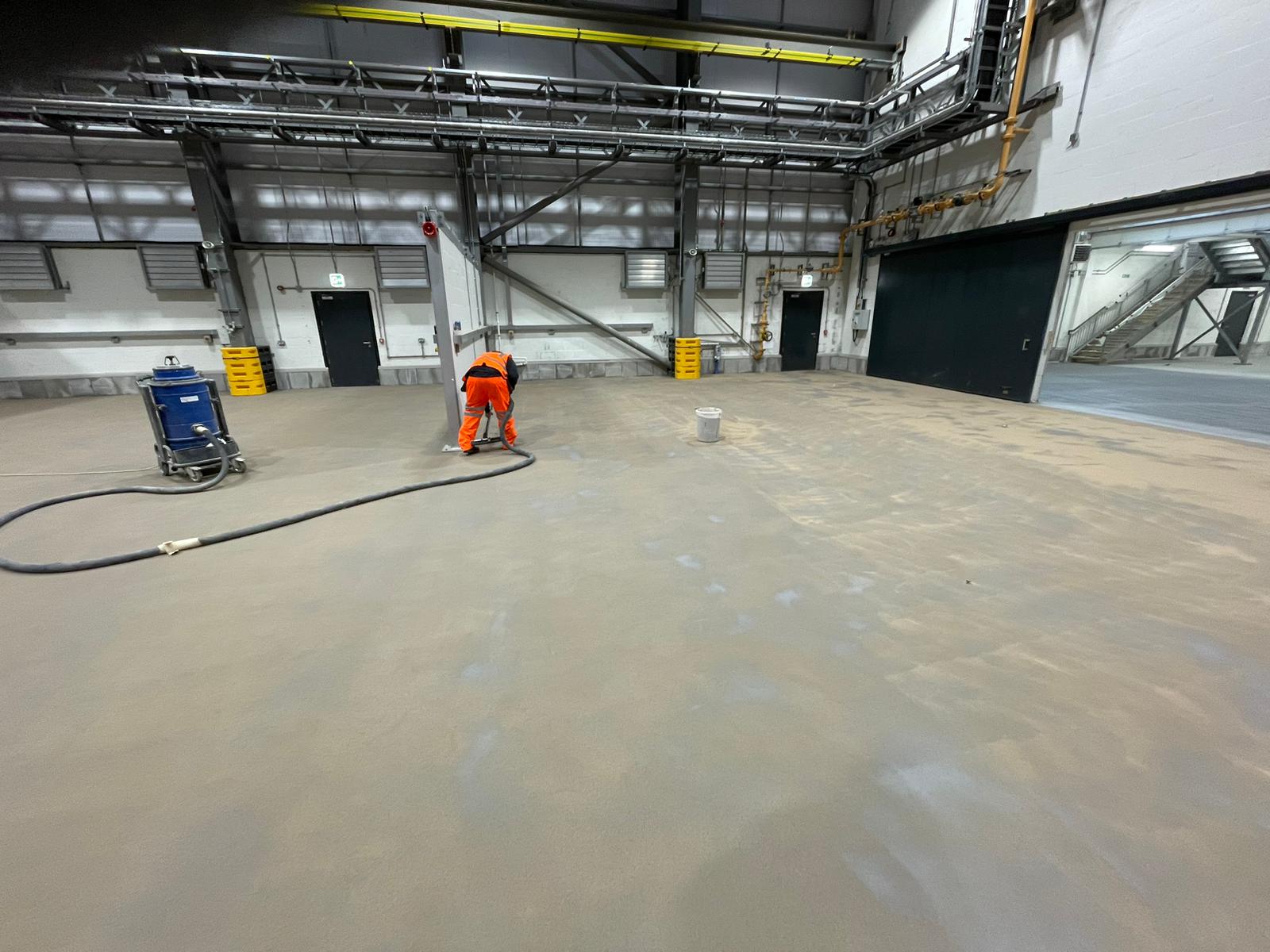

5,725sqm Train Shed Flooring Project

Surface Prep

To ensure optimal adhesion and performance, the guys began by mechanically prepare the substrate. This involved a combination of grinding and shot blasting, creating a clean and primed surface ready for application.

Scratch Coat & Slip Resistant Finish

To create a strong and durable base, we applied a high-build epoxy mixed with quartz sand as a scratch coat system. This was followed by an additional layer of broadcast quartz sand to enhance slip resistance. Finally, the surface was sealed with a top coat of high-build epoxy, delivering a slip-resistant finish that tested above 40 PTV (Pendulum Test Value) in both wet and dry conditions. (For context, a PTV reading of 36+ is classified as low risk for slip accidents.)

Final Touches

To complete the project, two coats of epoxy resin were applied to create the necessary demarcation lines, ensuring clear and durable markings for safe navigation within the trainshed. Additionally, the pit walls were treated with a water-based epoxy coating to provide a robust and lasting finish.