Industrial Resin Flooring Delivers Precision Flooring for a Precision Industry, with Flowcrete SF41.

Surface Preparation

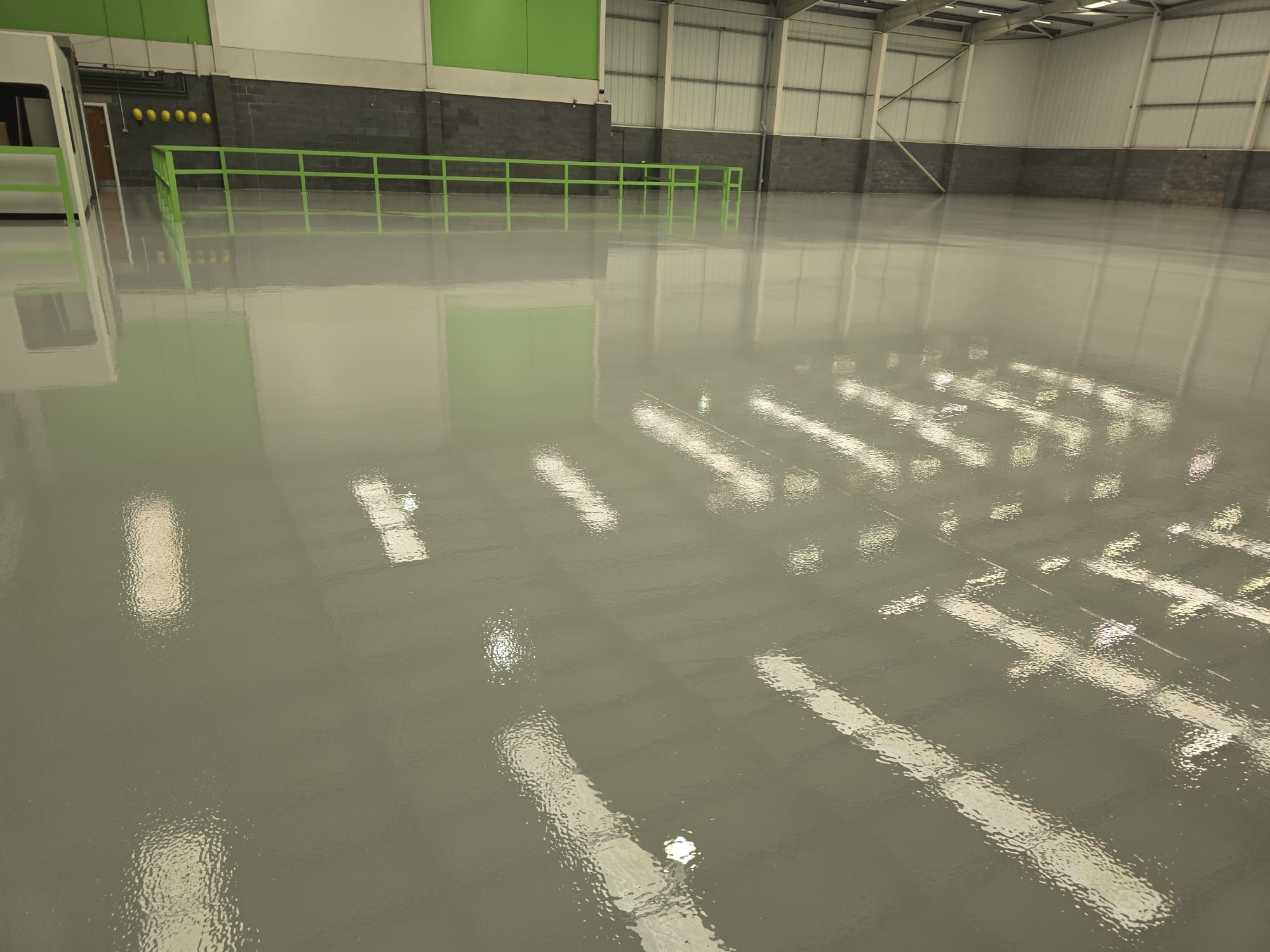

The surface was first diamond ground to remove contaminants and level imperfections. This was followed by a primer and two full coats of Flowcrete SF41, a high-build, solvent-free epoxy floor coating, renowned for its durability, chemical resistance, and customisable slip-resistance. The result was a seamless, non-slip, and hard-wearing finish designed to withstand pressure and provide long-term protection against wear, dust, and contamination. This made the resin flooring perfectly suited to the demands of the high-performance manufacturing environment.

Industry Leading Products & Experience

To showcase the newly refurbished facility and high-performance resin flooring, the company drew on its aviation heritage, featuring a decommissioned aircraft within the space. This symbolised the company’s commitment to precision, performance, and engineering excellence. Overall, this project demonstrated how the right combination of industry-leading products and expert installation can transform industrial environments and meet the demands of even the most critical sectors.